PRODUCTS

- Maintenance of Wastewater Treatment Plants

Modern perception about industrial waste treatment is moving further away from traditional solutions such as the collection and disposal of liquid waste abroad, a particularly costly method which unfortunately is still the norm for the majority of small companies – producers of hazardous waste. Moreover, the new environmental policy guides the industry to waste treatment solutions performed at the production site, thus simplifying the licensing procedures and mainly subsidizing the supply of such equipment, through the NSRF (ESPA) and Green Development programs.

SUK, having full knowledge of the new legal requirements, now proposes solutions and methods of timely and efficient waste treatment adapted to the specific nature of the waste and the needs of each customer. Having exclusive representation of significant European construction firms in Greece, such as ENVIROCHEMIE GmbH and LOFT GmbH, SUK has the ability to offer solutions for waste treatment to a very wide range of industrial activity, supplying the producer with modern machinery or undertaking the processing with mobile physicochemical waste treatment plants, which it owns.

SUK offers autonomous units of:

- Waste evaporation

- Physicochemical waste treatment

- Distillation of solvents

- Drying of physicochemical treated mud

- Wastewater Treatment Plants

Modern perception of industrial waste treatment is moving further away from traditional solutions such as the collection and disposal of liquid waste abroad, a particularly costly method. At the same time, the need to save water resources is constantly increasing and the environmental policy guides the industry to waste treatment solutions performed at the producer’s site, simplifying the licensing procedures and mainly subsidizing the supply of such equipment through the NSRF and Green Development programs.

SUK, having full knowledge of the new legal requirements, proposes solutions and methods of timely and efficient waste treatment adapted to the specific nature of the waste and the needs of each customer.

Having exclusive representation of significant European construction firms in Greece, SUK has the ability to offer solutions for waste treatment to a very wide range of industrial activity, supplying the producer with modern machinery or undertaking the treatment with mobile physicochemical waste treatment plants.

Waste treatment plants cover a wide range of industrial activities, such as:

- Aluminum industry

- Pharmaceutical companies

- Printing industry

- Galvanizing industry

- Landfill sites

- Refineries

- Printing shops

- ARC-SAFETY

ARC – SAFETY does not contain solvents; it is a roof coating that has a high content of acrylic styrene, ideal for re-coating of asbestos roofs and cladding sheets found in industrial buildings or large domestic garages.

Application

Apply two coats with a brush or a high-pressure spray, first applying the coating to the joints, the edges of the sheets and the substrate. Be careful when working with asbestos.

Preparation

The roof must be cleaned of all pollutants, including dirt and mold. The roof should be carefully inspected for construction defects and repaired before coating.

Coating

A 10 liters package is enough to cover an area of 25 m2 with 2 layers. Wait 4 to 6 hours before applying the second coat depending on weather / temperature. Do not apply at temperatures below 6˚C or if the temperature of the ceiling exceeds 32˚C. Do not apply during dry weather or if it is expected to rain within 6 hours from the final coat.

- Asbestos sampling kit

SUK launches a new innovative action and offers the asbestos sampling kit for the correct and safe sampling of suspicious solid materials for asbestos detection at a preferential price, in collaboration with the experienced scientific staff of our company. The asbestos kit includes:

- Disposable uniform (Category 3, Type 5) (1 pc)

- FFP3 mask for protection against fibers and particles (1 pc)

- Nitrile protection gloves (1 pair)

- Hand tools for removing the samples from the building materials of the facility (tweezers, straight screwdriver, spoon, cellophane tape)

- Wet wipes for cleaning tools between uses

- Polyethylene bags of various dimensions with airtight seal for the storage of samples.

- Waste evaporation

The Unit is suitable for the treatment of waste from various industrial sectors, such as:

- Emulsions (coolants and lubricants) and reagents which release mold during aluminum casting

- Restoration of Landfills

- Wastewater from cleaning of spare parts and machines

- Waste from pre-treatment plants (powder paint workshops, paint production)

- Galvanization, electrogalvanization

- Recycled liquids from deionization units

- Radioactive liquid waste

- Vibratory finish and much more which can be recycled with an economical, low energy consumption (energy consumption just between 50 and 70 Watt per liter), environmentally friendly LOFT Wastewater Evaporation Unit. Recycled water (distillate) can be disposed via drainage, since we ensure that the quality of the distillate is in accordance with applicable law. If the product of distillation is returned to the production process (recirculation), the water consumption as well as the volume of the solid residue is significantly reduced. In this case, assessing whether the recycled water is in accordance to the current legislation is not required, since the quality of the distillate to be distilled is determined by the customer. Unlike conventional methods, significant cost reduction is achieved via the aforementioned. Additionally, unlike physicochemical wastewater treatment plants, there is no need for any chemical additives.

Our clientele, using LOFT evaporators with a processing capacity ranging from 30 to 2200 liters per hour, covers the following industrial sectors:

- Car manufacturers

- Automotive suppliers

- Foundries / Refineries

- Companies for final disposal of waste

- Aircraft manufacturers

- Surface treatment of materials

- Cleaning of barrels

- Metal processing

- Landfill outflow

No. license of the Ministry of Environment & Energy: 152390/5124 / 14-11-2007

No. registration Ministry of Environment & Energy: 0003

- Waste management equipment and materials

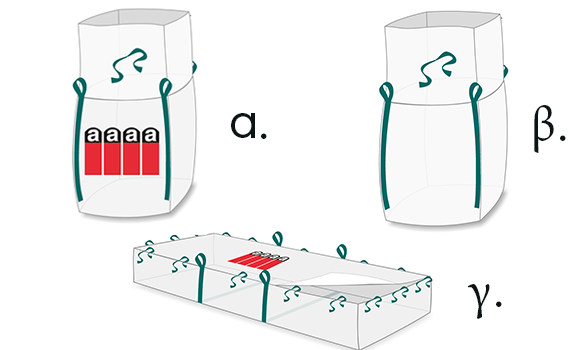

SUK provides empty type UN 13H3 big bags, suitable for the packaging of solid waste. The packaging is made in accordance with international and European standards for the collection and transport of hazardous waste. The types of packaging provided are:

- ENVIRO UN-ASBEST Big Bag 90x90x110

- ENVIRO UN-Big Bag 90x90x110 cm

- ENVIRO UN-Plattenbag 210x125x30 cm / 260x125x30 cm / 320x125x30 cm